Written by Leonor Rocha | Customer Success at PackIOT

Every organization has its own definition of culture. Even though we live in a globalized world, there will always be specific characteristics connected to the local and national culture that will define an organization.

Culture can be regarded as a collaborative journey of sensemaking, which can be described as a process that involves the cooperation of all parts that compose an organization, in order to raise awareness and understanding from different perspectives and interests of their individuals.

The culture of an organization has to be something in constant development, always shaping itself to the circumstances lived, as well as to the changes and to the evolution that occurs. So, whenever you decide to implement anything in your company, you should first think about your cultural roots. “It says that a crucial purpose of culture is to help orient its members to “reality” in ways that provide a basis for alignment of purpose and shared action.”

Creating the perfect data-driven team by reshaping the one you already have

Data analytics is probably one of the buzzwords of this century. Everybody wants to be part of a data-driven organization. Even though owning a good data analysis system can be easy, being able to make something out of it is another story. Being data-driven is not just about collecting data. There is actually no point in collecting it if you are not going to analyze it and use it to extract useful information.

If you own a factory, you probably are acquainted with the concept of having to deal with a tight budget. Investing in data analytics software can be quite an investment. That is why it should be a well-thought decision before taking the step of buying one. When acquiring such software, you have to keep in mind that there are several things you should take into account.

A lot of adjustments will have to be made, especially on your employees’ roles. A lot of processes will be simplified, and workers won’t have to spend the amount of time they used to, doing complex activities that required spending hours collecting data through manual processes.

Remote Data Access

By implementing an IoT analytics software in your factory, you will be able to check the state of your production wherever you are and whenever you need it. You will start having direct access to your production data on your smartphone with just one simple click. The majority of these software providers, offer a mobile version that enables you to check your production lines at any time. It makes every managers’ life much easier. You won’t have to stay at the factory to have access to your data.

Employees Engagement

So far, we have no form of strong AI technology in the world, which means that every smart technological process that exists, still requires human support to work according to the expected.

If you implement analytics software in your factory, you will have to provide the right training to your operators. A poor initial training process can influence the entire implementation process, which can mean a waste of time and money if the employees do not know how to work with the program. To have an analytics software successfully running at your factory, you must have well-trained operators to have the right data outputs.

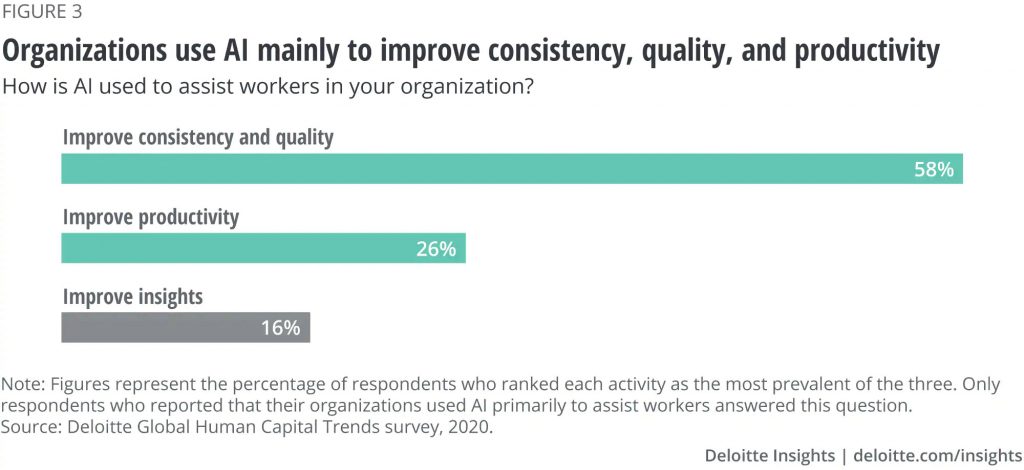

“Fifty-nine percent of organizations say the redesign of jobs to integrate AI technology is important or very important for their success over the next 12 to 18 months, but only 7 percent say they are very ready to address this trend.” in Deloitte

Report Automation

The best part of implementing analytics software in your factory is not needing to have manual inputs anymore. From the moment you have software like this running, your operators will not need to waste tons of time inserting the production data manually.

Everything becomes automatic, you will just have to make sure that the sensors are in the correct place so that their count remains stable. It is extremely important to constantly check the sensors, because if there is the case of them counting too high or too low, the data outputs will not be 100% correct and accurate, misleading you in relation to the data you are receiving.

Better And Easier Decision Making

Data analysis provides certain valuable insights that can be critical in decision making. By automating your data storage processes, you will be able to have access to immediate data outputs related to unannounced machine stops, scrap rates, daily production numbers, among other metrics. Thereby you will be able to know exactly where you should invest money in your infrastructure. Should you acquire new machines, or should you get raw materials with higher quality? Data analysis software can help you answer this type of question.

Answering our initial question, an analytics system can reshape the culture of your manufacturing team as it will simplify a lot of complex daily processes, if well used. There will not be manual data inputs anymore, and the story of writing the info on a paper and then pass everything to excel will also end. Analytics software can be your lifesaver and the answer to your questions.

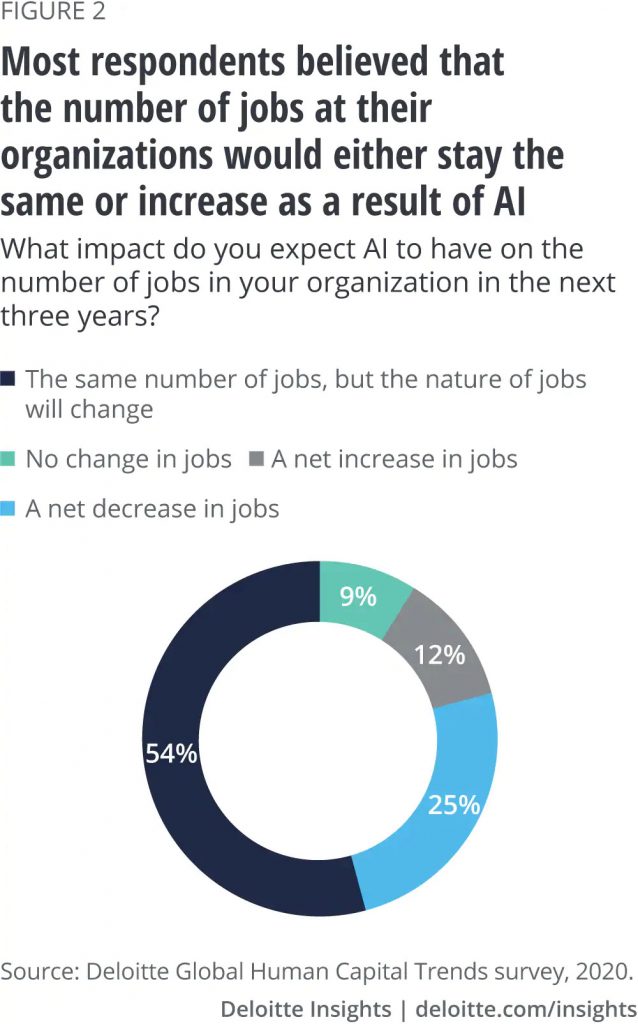

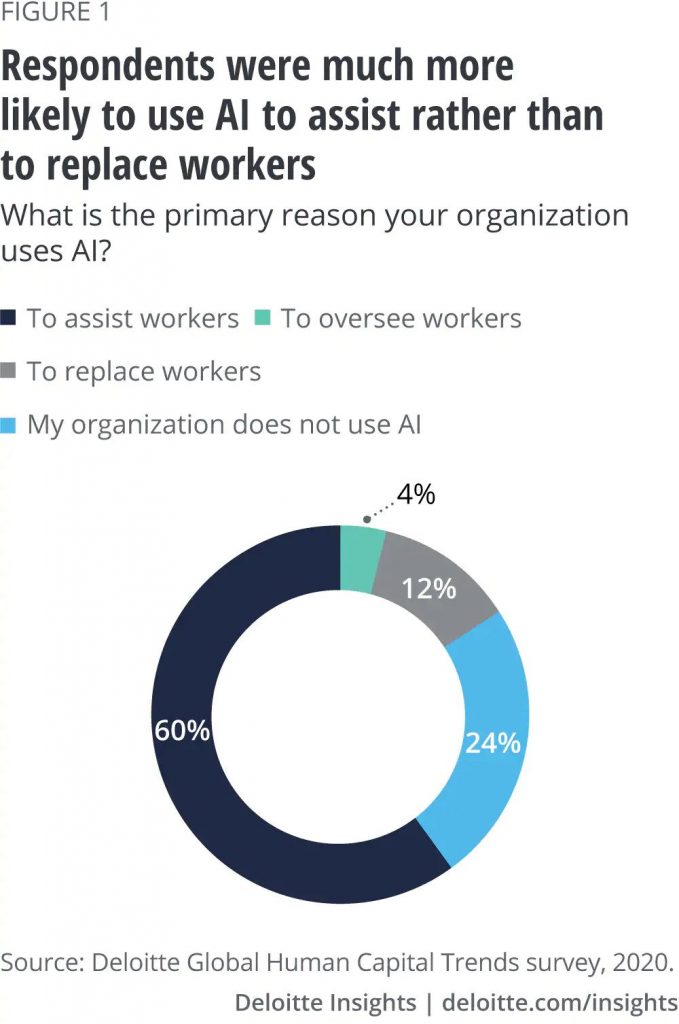

All images belong to Delloite Global Human Capital Trends Survey, 2020.