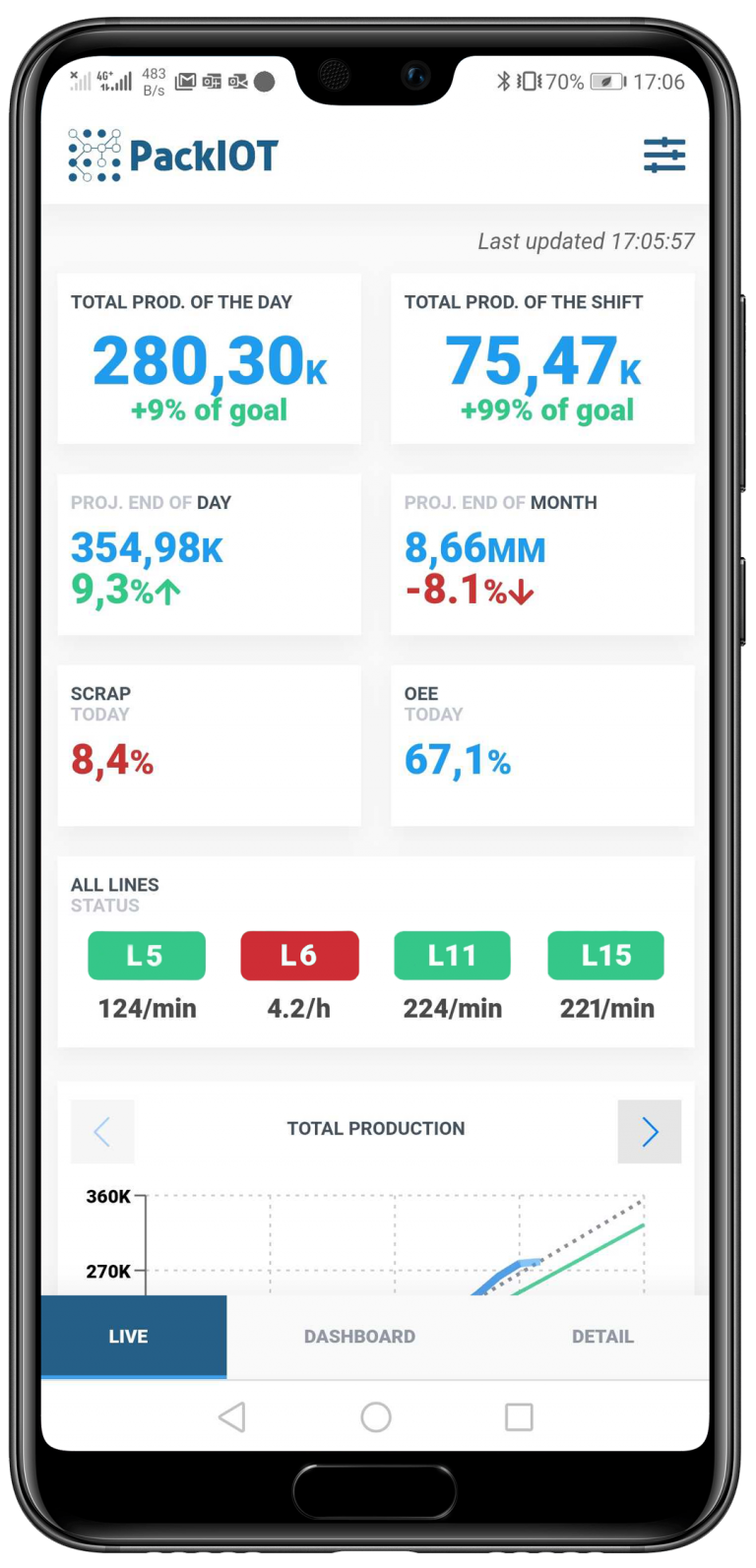

#1 analytics software for the packaging industry

Automatic real time information to reduce costs increase productivity improve engagement

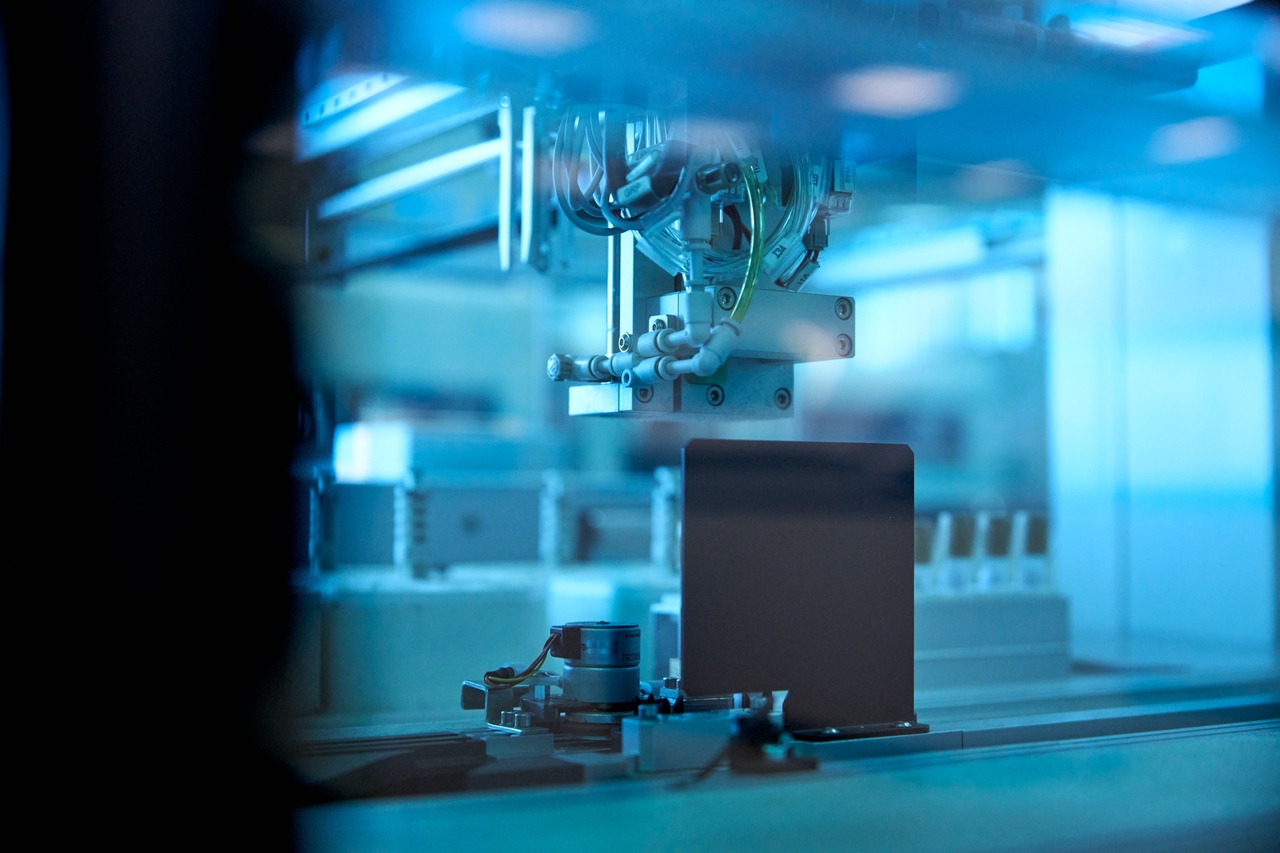

EASY AND SIMPLE INDUSTRY 4.0 TOOL FOR packaging manufacturers

PackIOT is the only plug-and-play, cloud-based production software for data collection and analysis for the packaging industry.

With our unique 2 days installation process, our software helps you to identify the existing problems by providing deep insights into your factory’s data. You will start making better decisions and coming up with efficient solutions for your business.

We are fanatical for industry efficiency, big data, machine learning and data-driven decisions.

KEY BENEFITS

Simple and easy 2 days installation, executed by a team of packaging and tech experts

Production Info and KPIs

- Scrap source analysis

- Pareto of main downtime reasons

- OEE in Real Time

- Out-of-the-box dashboards for the factory

- Analysis by Shifts and Teams

Integrations and Resources

- Cloud Native

- Integrates with your ERP System

- Works with both new and legacy machines

- Multiplant visibility

- Multidevice view

ROAD TO SUCCESS

start building an outstanding efficient future with our UNIQUE free trial MODEL

Business Alignment

Our mission is to help you to achieve your business KPIs.

Installation and System Setup

With your inputs, we bring your needs and parameters into PackIOT, all remotely

Deployment and Training

Our gateway gets connected to your existing PLC’s and in only 2 days PackIOT is running. No local servers needed!

Constant Improvement

Our Customer Service team will be always available to help you get insights from your data and drive improvements.

Do you want to improve the quality

of your factory data?

REAL RESULTS

→ up to 80% of time reduction in manual data logging

→ 70% faster reaction to downtime

→ ROI in weeks, not years

→ 98% of operator engagement on the platform

→ Immediate identification of bottle necks

→ User-centric software, generating value for everyone

OEE

Understand where is the biggest potential of improvement in your factory

SCRAP

Automatically track your scrap rates

DOWNTIME REASONS

All downtime motives available to everyone. Operators love it!

PRODUCTION FLOW

Identify your bottle necks and act upon them

Automatic Alerts

Get an SMS if your line is down for over a certain period

Change over tracking

Know how long your setup is taking and improve it

Some of our happy customers

Satisfied clients around the globe

What our clients say

WE ARE DIGITAL TRANSFORMATION FANATICS

Our mission is to help packaging manufacturers initiate or improve their digital transformation journey. Through IOT, Big Data and Machine Learning we have been helping our clients to access powerful reports and get actionable insights to run their businesses more efficiently.

The Growing Significance of ESG in Manufacturing

ESG: you’ve probably heard this acronym recenly, right? In today’s rapidly evolving industrial landscape, the role of Environmental, Social, and Corporate Governance (ESG) criteria has

Why Data Visualization is Crucial for Gaining Actionable Insights into Your Metrics

In an industrial landscape where data is the new oil, organizations are tirelessly working to extract, process, and make sense of an ever-growing sea of

Industry 5.0: The Human Touch in the Fourth Industrial Revolution

We live in a time of rapid technological advancements, where Industry 4.0 is already revolutionizing how businesses operate, with automation and intelligent technologies becoming increasingly

The top five most digitally mature industry sectors in 2022

According to an international report launched by the World Economic Forum – in partnership with the Singapore Economic Development Board (EDB) – the top five

FAQ

Some questions you might have.

PackIOt can be integrated with MES and ERP systems. We can export data from predefined formats, which can be imported and connected to existing systems. For example, the information on POs can be imported to PackIOT’s system through CSV documents, or by integrating with the current one which already carries this information.

Depending on how many lines you have and in how many sensors per line you will need, you will need one or more of the following: TVs for the lines, CLPs and Raspberry Pi Kits to connect to our cloud, and tablets for the operators.

With our software, you will be able to have information about the OEE of your factory, the scrap rates of your lines/machines, how are the numbers of production every day, week and month, for how long did the machines stop.

Our software does not require any kind of special customization, which means that we can offer a low-cost solution which is plug and play, with no need of having someone at the factory for a long time to install and train people.

Our implementation process takes about two months, from the moment we start discussing the first details, until the moment we have everything set to start running PackIOT at your factory.

Yes, besides getting data from the PLC it is also possible to use existing sensors from machines. The signals are then sent to an additional PLC (programmed by PackIOT) and then processed. Normally two signals by machine are enough: one of input, reading parts being fed into the machine , and one of output, reading the amount of good parts being produced.