Industry 5.0: The Human Touch in the Fourth Industrial Revolution

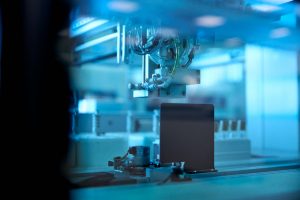

We live in a time of rapid technological advancements, where Industry 4.0 is already revolutionizing how businesses operate, with automation and intelligent technologies becoming increasingly prevalent in industrial processes. However, as we embrace the era of digitalization and smart factories, there's a growing recognition that technology alone is not enough to create sustainable and meaningful progress. To achieve that, we need to balance technological innovation with a human touch – and that's where Industry 5.0 comes in. What is Industry 5.0? Industry 5.0 is a concept that represents the convergence of the latest technological advances with human-centric values, ethics, and principles. It aims to put human beings at the center of industrial processes and empower them to leverage the full potential of new technologies while focusing on social responsibility, environmental sustainability, and overall well-being. Industry 5.0 builds on the three previous industrial revolutions, each of which brought significant changes to the way we work and live: Industry 1.0: The first industrial revolution started in the late 18th century with the invention of the steam engine, which marked the transition from manual labor to machine-based manufacturing. Industry 2.0: The second industrial revolution began in the early 20th century…